Creating the Connected Future

Human ingenuity coupled with intelligent machines

AI to contribute $15.7 trillion to the global economy by 2030, with manufacturing reaping substantial benefits.

Elevate performance metrics with advanced digital twin software. Simulate and predict setup and material demand, assess workforce impact, and optimize scenarios for increased utilization and performance, driving higher margins

In a world of scarce time and resources, the Industrial Copilot for Planning maximizes efficiency by optimizing resource allocation and crafting optimal strategies through diverse planning scenarios

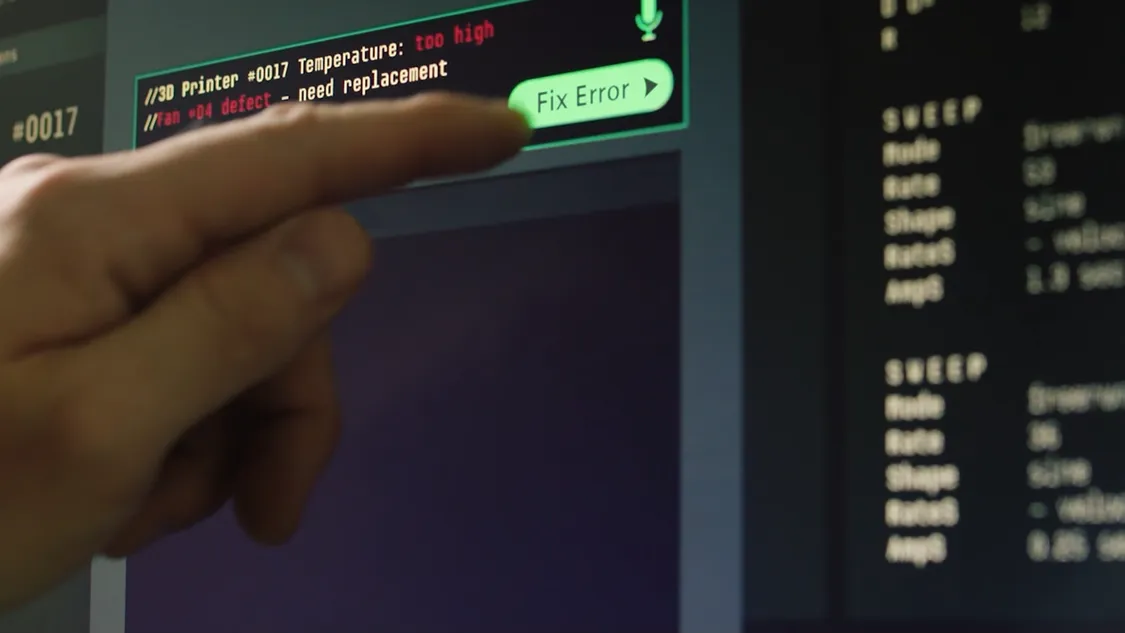

The Industrial Copilot for Engineering revolutionizes the engineering process, swiftly generating, optimizing, and debugging complex automation code. Engineers delegate repetitive tasks, slashing workloads and accelerating development

The Industrial Copilot for Operations empowers operators and maintenance engineers to interface with machines using intelligence from existing documentation and real-time process data via IIoT and edge devices

Machine information can be exchanged between different systems regardless of how it is stored in those systems.

Upgrade your factory infrastructure to become intelligent and interconnected, facilitating the integration of various smart manufacturing applications and solutions to boost efficiency and productivity.

Develop rapid multi process to identify, exercise and implement initial use cases.

Deployment of unique solutions. Promote industry wide standards

and adoption.

Experience the seamless, automated processes other Industrial organisations rave about.

Instead of asking patients to download an app or log into a portal, we deliver the right message at the right time.

Secure ISO 23247 compliant platform for creating digital twins of manufacturing elements, including personnel, equipment, materials, processes, facilities, environment, products, and documents.

Shifting to omni-channel models to build personalized engagement and stronger relationships with healthcare professionals, which will ultimately translate into better care for patients.

Artificial intelligence (AI)-driven automation and FIHR integrations improve patient and member experiences.

Leverage task-based workflows to manage referrals, billing, claims, health inquiries and care transfers.

Patients and members want holistic support. Give them the digital tools and multichannel experiences they expect.

96% of online patient complaints center around customer service — not quality of care.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |